What is Shot Peening?

A process widely used in manufacturing mechanical parts, shot peening is known for hardening the surface of metal components to prepare them for use. As the life of these parts will often be repetitive & stressful, fractures and breaks are liable. Shot peening is used to reinforce the surface of the metal, strengthening the fatigue resistance.

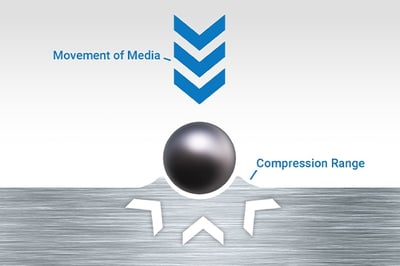

Shot peening is a cold work process when a media in the form of small circular objects is shot at a metal subject with enough force that results in a small dent to the surface. The media can be metal, glass or ceramic, with multiple of the small ball-bearing sized objects used to create multiple tiny indentations to the surface. As each impact indents the surface, the directly targeted area will cave in with surrounding (softer) material pushing to the sides into the compression range. Because lots of media is aimed at the area, the compression range will be repetitively hit causing the overall area to be compressed & encased in a compressively stressed layer.

Benefits of Shot Peening

- Strengthens the surface of the metal.

- Increase fatigue resistance, increasing the functional longevity of the item.

- Reduces the possibility of cracking.

- Remove unwanted tension in the material (from previous processes).

- Fills out surface pores.

- Produces a ‘pebbly’ surface which is desirable with certain components.

- Dislodge small debris.

Due to the compression, shot peening can marginally distort the surface of the metal which could be problematic for parts that require precision. For these circumstances particle shot peening would be used, as it uses a smaller medium that could be more carefully controlled.

Who Uses Shot Peening?

Commonly used in the medical, aerospace & automotive industries, shot peening is used for an extensive range of items such as gears, springs, rods, crankshafts, pistons, drill bits, propeller shafts, turbine blades, epidural gear & much more.

Machines for Application

When it comes to shot peening there are two types of machines that can achieve the desired effect, air blasting machines & centrifugal wheelblast machines. As each has its advantages, it is common that specific components are more suitable to be hardened by one machine rather than the other.

Air Blasting

Utilizing compressed air to shoot media at the surface, air blasting machines are precise and efficient, firing the media via a nozzle. Requiring to be connected to an air supply, these machines can accurately control the speed the media is fired at. Their design can vary, frequently seen as self-contained blast rooms, abrasive blast cabinets or portable equipment, potentially containing multiple nozzle guns for increased coverage.

Centrifugal Wheelblast

To shoot its media and implied by its name wheelblast, these machines use a high-speed paddle wheel to fire their media. These machines are often called airless blasting machines to differentiate the pending technology from air blast machinery. Able to fire at a speedy rate, the movement of the wheel is directly driven or belt driven. All this takes place inside a closed chamber, the centrifugal force allowing for even coverage to the surface of all the parts inside.

Comparison

Upon comparison, both these machines are very efficient at shot peening so deciding on which to use for different components is dependent on their strengths.

Air Blasting | Centrifugal Wheelblast |

- Accurate & precise

- Thorough & in-depth

- Optional forms of blast rooms, cabinets portable equipment

|

- Shorter time cycles

- Process larger batches or larger items

- The volume of media shot will process a larger area

|

If you are looking for a shot peening machine but are unsure on which machine to buy, you can contact our team for more information at [email protected] or call us at +44(0)1922 45 8000.

Dynamiki Dynablaster M11 Suction Venturi Shot Blast Machine

The M11 suction feed cabinet is a general purpose heavy duty workshop machine suitable for a wide range of blasting applications. Designed for easy access with a large front opening door

- Stock No

- NEW130

- Category

- Suction Venturi Blast Cabinets

- Model

- Dynamiki M11

- Work Envelope (WxDxH mm) [?]

- 1000 x 700 x 1000

- Work Handling Method

- Manual

- Condition

- Brand New, Current Model

- Availability:

- Available subject to build time

- Price [?]

- Please call on +44 (0) 1922 45 8000

Dynamiki Dynablaster M12 Suction Venturi Shot Blast Machine

The M12 suction feed cabinet is a general purpose heavy duty workshop machine suitable for a wide range of blasting applications. Designed for a smaller floor space with rear mounted dust collector.

- Stock No

- NEW131

- Category

- Suction Venturi Blast Cabinets

- Model

- Dynamiki M-12

- Work Envelope (WxDxH mm) [?]

- 1000 x 800 x 950

- Work Handling Method

- Manual

- Other Info

- 400v 3 phase

- Condition

- Brand New

- Availability:

- Available subject to build time

- Price [?]

- Please call on +44 (0) 1922 45 8000

Riley 1200 Pressure Shot Blast Cabinet

The Riley pressure fed shot blasting cabinet with an 8 litre pressure pot for high quality finishing. Includes a front opening door for easy component handling and a matched dust collector.

- Stock No

- NEW151

- Category

- Pressure Fed Blast Cabinets

- Model

- Riley Various

- Work Envelope (WxDxH mm) [?]

- 1200 x 1000 x 850mm

- Condition

- Brand New, Excellent Condition, Current Model

- Availability:

- Available subject to build time

- Price [?]

- Please call on +44 (0) 1922 45 8000

Riley Auto Alloy Wheel Blaster

Quick and quality automatic blasting of alloy wheels. Reduces staffing costs and increases throughput (approx 3.5 minutes per wheel) with a consistent quality finish, Airless technology.

- Stock No

- NEW200

- Category

- Airless & Automated Blast Equipment

- Model

- Riley Auto Wheel Blaster

- Work Envelope (WxDxH mm) [?]

- 1x Alloy Wheel

- Work Handling Method

- Automatic

- Other Info

- Fast, airless blasting

- Condition

- Brand New

- Availability:

- Available subject to build time

- Price [?]

- Please call on +44 (0) 1922 45 8000

Surface Dynamics Automated 4 Gun Twin Axis Shot Peening System

This blasting system is designed for the automatic cleaning of jet engine blades. The blast cabinet includes a powered turntable and fitted to a linear actuator are 4 blast nozzles. Media recovery including sieving for re-use is also used, plus a powerful dust extraction system.

- Stock No

- SB957

- Category

- Airless & Automated Blast Equipment

- Model

- Surface Dynamics ALOX 180 Auto Blasting

- Year of Manufacture

- 2007

- Work Envelope (WxDxH mm) [?]

- 1010 x 700 x 1130

- Work Handling Method

- Manual Load Rotary Table 4 x Recip' Guns

- Other Info

- Programmable auto Blast Process

- Condition

- Refurbished by RSW, Excellent Condition, Current Model, Seen powered at RSW

- Refurbished Price [?]

- £ Login or Register for price.

- Sold As Seen Price [?]

- £ Login or Register for price.

Vacublast (Wheelabrator) Ventus 150S, Semi Automated Blast Machine

The Wheelabrator Vacublast Ventus model 150S Semi Automatic Peener is a suction feed air blast cabinet that has been designed specifically for production applications where a less aggressive surface treatment is required.

- Stock No

- SB976

- Category

- Airless & Automated Blast Equipment

- Model

- Vacublast (Wheelabrator) Ventus model 150S

- Work Envelope (WxDxH mm) [?]

- 1500 x 1300 x 900

- Work Handling Method

- Semi Automatic

- Other Info

- Unimaster UMA 152 Dust Collector

- Condition

- From a working environment, Seen working by RSW, Good Condition

- Refurbished Price [?]

- £ Login or Register for price.

- Sold As Seen Price [?]

- £ Login or Register for price.

Vixen Surface Treatments JB 220 Jetblast Machine

The Jetair JB220 is ideally suited to cleaning components which can be tumble-blasted using steel shot to remove rust, scale and paint such as those in the re-manufacturing industries. Very low run hours.

- Stock No

- SB983

- Category

- Airless & Automated Blast Equipment

- Model

- Vixen Surface Treatments JB220

- Year of Manufacture

- 2000

- Work Envelope (WxDxH mm) [?]

- Ø525 x 700

- Work Handling Method

- Manual load auto blast

- Other Info

- Compact Airless Tumble Blast

- Condition

- Good Condition, Current Model, Seen powered at RSW

- Refurbished Price [?]

- £ Login or Register for price.

- Sold As Seen Price [?]

- £ Login or Register for price.

Wheelabrator Wheelabrator M101 Self Contained, Fully Packaged, Tumble Belt Shotblast Machine

The Wheelabrator M101 shot blast machine offers a low-cost solution to batch clean tumble-proof components in the most efficient and economical way. PLC has lost memory, replacement or re-program required.

- Stock No

- SC1017

- Category

- Airless & Automated Blast Equipment

- Model

- Wheelabrator Tumble Blast M101

- Work Envelope (WxDxH mm) [?]

- 825 x 600

- Work Handling Method

- Manual load, Automatic cycle

- Other Info

- PLC has lost memory, replace or re-Prog

- Condition

- Good Condition, Seen powered at RSW

- Refurbished Price [?]

- £ Login or Register for price.

- Sold As Seen Price [?]

- £ Login or Register for price.

Wheelabrator Vacublast, Very Heavy Duty, Automatic, Programmable, Vector 150P Shot Blast Cabinet

The Ventus 150P pressure fed air blast cabinet from Wheelabrator has been refurbished and upgraded to include the latest in HMI control and designed for specific production applications where a high work output is required.

- Stock No

- SD1023

- Category

- Airless & Automated Blast Equipment

- Model

- Wheelabrator Programmable Ventas 150 P Automated

- Year of Manufacture

- Ref 2018

- Work Envelope (WxDxH mm) [?]

- 1500 x 1400 x 1190

- Work Handling Method

- Load End Driven Table Auto X & Y Axis

- Other Info

- Touch Screen program Controller (2018)

- Condition

- Good Condition, Seen powered at RSW

- Sold As Seen Price [?]

- £ Login or Register for price.

Wheelabrator Nova PB 80 Pressure Fed Shotblast Cabinet with Dust Extractor

The Vacublast Model Nova PB 80 designed to provide quick, clean and efficient results across a wide range of blast cleaning applications.

- Stock No

- SD1025

- Category

- Pressure Fed Blast Cabinets

- Model

- Wheelabrator Nova PB 80

- Year of Manufacture

- 1978

- Work Envelope (WxDxH mm) [?]

- 800 x 600 x 600mm

- Work Handling Method

- Manual

- Other Info

- ATEX Rated Explosion Relief Panel Dusty

- Condition

- Seen working by RSW, Excellent Condition

- Refurbished Price [?]

- £ Login or Register for price.

- Sold As Seen Price [?]

- £ Login or Register for price.

Guyson International 1400 Mediblast Shot Blast Cabinet with Extractor

The Guyson Mediblast range made from high chrome 316L surgical stainless steel has been specially engineered for medical product manufacturers and laboratories where the introduction of ferrous contamination would be detrimental to the production process. Includes C400 3 dust extractor.

- Stock No

- SD1037

- Category

- Suction Venturi Blast Cabinets

- Model

- Guyson International 1400

- Year of Manufacture

- 2010

- Work Envelope (WxDxH mm) [?]

- 815 x 560 x 591

- Work Handling Method

- Manual

- Other Info

- Fully Stainless Steel Construction

- Condition

- From a working environment, Excellent Condition, Current Model

- Refurbished Price [?]

- £ Login or Register for price.

- Sold As Seen Price [?]

- £ Login or Register for price.

Guyson International DBH 4 Shotblasting Cabinet with Dust Extractor

The Guyson DBH 4 machine boasts exceptional component entry facilities and sleeved armholes which provide safe and comfortable operator access. Including matching dust extractor, foot pedal operation and internal lighting.

- Stock No

- SD1040

- Category

- Suction Venturi Blast Cabinets

- Model

- Guyson International DBH 4 Cabinet & DC41 Extractor

- Work Envelope (WxDxH mm) [?]

- 535 x 762 x 812mm

- Work Handling Method

- Single Front Manual Door

- Other Info

- Suction venturi blast cabinet 6mm nozzle

- Condition

- Good Condition

- Sold As Seen Price [?]

- £ Login or Register for price.

Odlings MCR R100 Rotoblast, Barrel Blast Machine

The Rotoblast 100 shot blasting cabinets have been used in various industries for blast cleaning parts like turbos, transmission cases, scaffolding clips, calipers and brake shoes in the re-manufacturing industries.

- Stock No

- SE1051

- Category

- Airless & Automated Blast Equipment

- Model

- Odlings MCR Rotoblast 100

- Year of Manufacture

- c.2012

- Work Envelope (WxDxH mm) [?]

- Ø570mm x 1100mm long

- Work Handling Method

- Manual Load Auto Barrel Rotation Blast

- Other Info

- Twin Blast Motors & Drum Rotation

- Condition

- Good Condition, Current Model, Seen powered at RSW

- Refurbished Price [?]

- £ Login or Register for price.

- Sold As Seen Price [?]

- £ Login or Register for price.

Sealey Products Shot Blast Cabinet

This heavy-duty steel cabinet features a toughened glass viewing screen for enhanced durability and visibility. The Sealey shot blasting cabinet, in like-new condition, is an excellent choice for shot blasting with glass beads, silicon carbide, aluminium oxide and blasting grit.

- Stock No

- SE1057

- Category

- Suction Venturi Blast Cabinets

- Model

- Sealey Products SB973

- Year of Manufacture

- c. 2023

- Work Envelope (WxDxH mm) [?]

- Door opening 480 x 245/410mm

- Work Handling Method

- Manual

- Other Info

- Very Little Use

- Condition

- Excellent Condition, Unused, Current Model

- Sold As Seen Price [?]

- £ Login or Register for price.

Rosler Rotary Table Semi Auto Blast Cabinet With Full Recovery

This second hand Rosler ST 1400 blast cabinet configured for the automatic processing of multiple jigged components, however can accommodate bulky, large or heavy components. The cabinet is equipped with motorised rotating table upon which fixtures or jigs can be mounted to make this a semi automatic blasting machine.

- Stock No

- SE1066

- Category

- Suction Venturi Blast Cabinets

- Model

- Rosler ST 1400 PS

- Year of Manufacture

- 2008

- Work Envelope (WxDxH mm) [?]

- Table 900 Ø x 400

- Work Handling Method

- Semi Automatic rotary table.

- Other Info

- Used as standard M/C or semi Automatic

- Condition

- From a working environment, Good Condition, Current Model

- Refurbished Price [?]

- £ Login or Register for price.

- Sold As Seen Price [?]

- £ Login or Register for price.

Machines & equipment for sale

- Surface Treatment

- Cleaning & Degreasing

- Polishing & Belt Linishing

- Mass Finishing

- Ovens & Furnaces

- Process Cooling

- Shot Blasting

- Dust & Fume Extraction

- Air Compressors

- Rectifiers & Transformers

- Miscellaneous

- Latest Stock

- Special Offers

- Direct From Site Clearances

- Auctions

- Brand New Machines

- Available Immediately

- Sell Your Machine

Machine Alert

Get the latest machines emailed directly to you as they become available to buy online. Sign Up Now