T Masters and Sons Ingot Casting Machine

- Stock No

- MC895S

- Manufacturer

- T Masters and Sons

- Model

- Automatic Ingot maker

- Year of Manufacture

- 2016

- Serial

- 394/716

- Condition

- Excellent Condition, Ex demonstration, Current Model

- Internal Size (WxDxH mm) [?]

- 70 x 25Kg Ingots

- Other Info

- 70 x Bolt on ingot moulds

- Location

- Our Central Warehouse, Aldridge, UK

- External Dimensions (WxDxH mm) [?]

- 1400 x 6160 x 4200mm

- Delivery Your delivery options

Description

This ingot casting machine with 160 Fitch Chain is designed to process 70 moulds of 25g Ingots (copper) cones.

The Master's Ingot Casting Machine has been designed to work in conjunction with modem melting and refining furnaces as a means for the automatic production of metal ingots.

The machine achieves greater production at a lower cost, reducing the number of skilled operators while casting ingots of good shape and appearance.

During the design of the casting machine, special attention was paid to reliability and simplicity in operation and for cost-effective protection with minimum maintenance.

The principal part of the machine is an endless conveyor chain carrying the ingot moulds whether bolt-on or in a slipper. From the furnace tapping point the molten metal streams through a launder into one or two pouring devices, which are automatically actuated to pour the ingots while they are passing through the pouring station.

At the discharge end of the conveyor, the ingots are solidified and subsequently ejected by a knockout system.

This machine was sold in 2024 to a EU based company commercialising an R&D project processing specialist stainless steel alloys. |

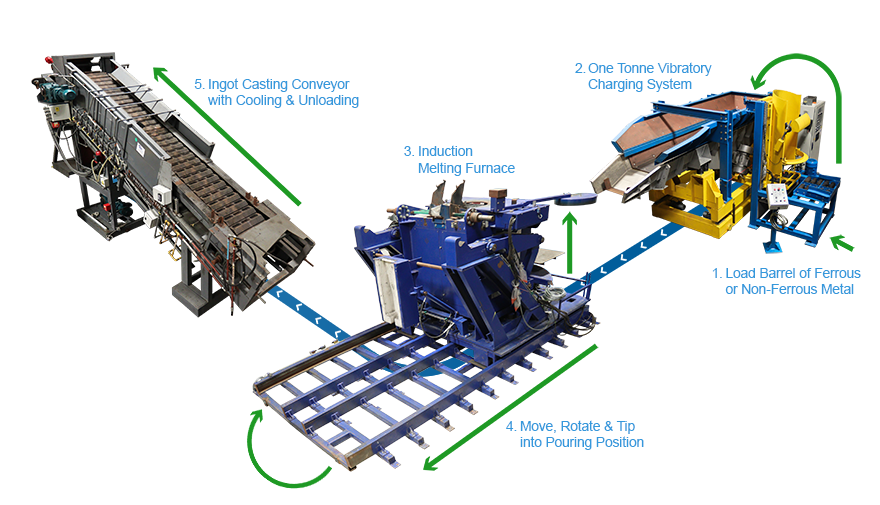

Ferrous & Non-Ferrous Melting & Ingot Casting Production Cell

This machine was installed as part of a production cell at Morgan Advanced Materials UK, comprising of three key machines

- Foundry Projects Ltd One Tonne Capacity Mobile Vibratory Charging System

- Induction Heating Systems Limited Induction Melting Furnace - SOLD

- [This machine] T Masters and Sons Ingot Casting Machine

Ingot Casting Process

Masters Ingot Casting Machines are typically individually built to the customer's requirements, they have the following design principles:

Main Frame

The main frame of the machine is a steel fabrication with channel section base.

Conveyor Chains

These endless chains are constructed of mild steel links and hardened rollers. Suitable brackets are welded to the inside of both chains at each pitch to support the mould carriers.

Bolt on Type Moulds

Each mould has lugs which are machined and drilled for bolting directly to the conveyor chain across each pitch.

Pouring Equipment

The automatic pouring equipment consists of one pouring tray, which is mounted over the end of the conveyor chain in yokes and brackets so that it can perform a tilting motion. The drive for the pouring ladles is mounted at the side of the machine, with the ladle drive gear mounted at the end of the main chain sprocket shaft, driving the ladle through a set of gears and a single drive chain. The pouring motions of the ladle are controlled by a cam and a linkage, which synchronise the motions to the conveyor speed.

Main Drive

The machine is powered by a totally enclosed fan-cooled AC motorised gear unit shaft mounted to the head shaft of the main conveyor.

Knockout

At the discharge end of the machine, a knockout mechanism is provided. A pair of roller hammers strike each mould as they pass over the drive sprocket, ejecting the ingots onto a discharge chute or collection bin.

Water Cooling

A water cooling system is provided to assist in the cooling of the ingots. By individual valves controlled jets are arranged above the ingots, while a further set of jets is provided internally to discharge water over the back of the returning moulds.

This water cooling system must be connected to the water mains in the shop

Air Cooling

Three bifurcated fans are mounted over the casting machine to cool the product as it passes through the cooling zone. A further set of ten fans are mounted underneath cooling the empty returning mould.

Dimensions

- Overall: 1400mm x 6160mm x 4200mm

- Length Tip to Tip: 3960mm

- Castor: 1300mm (length) x 550mm (widest point)

- Conveyor Belt: 820mm Wide, 540mm Width Actual

- Dimensions Per 3 Castings: 140mm x 50mm x 40mm

![]() Print / Download T Masters and Sons Ingot Casting Machine Datasheet

Print / Download T Masters and Sons Ingot Casting Machine Datasheet

Photographs taken prior refurbishment. Our refurbishment service is not available on all machines.

Machines & equipment for sale

- Surface Treatment

- Cleaning & Degreasing

- Polishing & Belt Linishing

- Mass Finishing

- Ovens & Furnaces

- Process Cooling

- Shot Blasting

- Dust & Fume Extraction

- Air Compressors

- Rectifiers & Transformers

- Miscellaneous

- Latest Stock

- Special Offers

- Direct From Site Clearances

- Auctions

- Brand New Machines

- Available Immediately

- Sell Your Machine

Machine Alert

Get the latest machines emailed directly to you as they become available to buy online. Sign Up Now