Ebara 3M/I 32-160/1.5 Centrifugal Electric Pump in Stainless Steel

- Stock No

- MD912

- Manufacturer

- Ebara

- Model

- 3M/I 32-160/1.5

- Year of Manufacture

- 10-2022

- Serial

- 13002024041

- Condition

- From a working environment, Excellent Condition, Current Model

- Capacity

- Max. 333 l/min 20m3/h

- Process Application

- Multiple Fluid Transfer Applications

- Other Info

- 1.5kW 2hp

- Location

- Our Central Warehouse, Aldridge, UK

- Weight (kgs)

- 22

- External Dimensions (WxDxH mm) [?]

- 254 x 431 x 292

- Delivery Your delivery options

Description

Ebara 3M/I 32-160/1.5 Monobloc with Extended Motor Shaft Centrifugal Pump

A Centrifugal Pump is a mechanical device designed to move a fluid by means of the transfer of rotational energy from one or more driven rotors, called impellers. Fluid enters the rapidly rotating impeller along its axis and is cast out by centrifugal force along its circumference through the impeller’s vane tips. The action of the impeller increases the fluid’s velocity and pressure and also directs it towards the pump outlet. The pump casing is specially designed to constrict the fluid from the pump inlet, direct it into the impeller and then slow and control the fluid before discharge.

How does a centrifugal pump work?

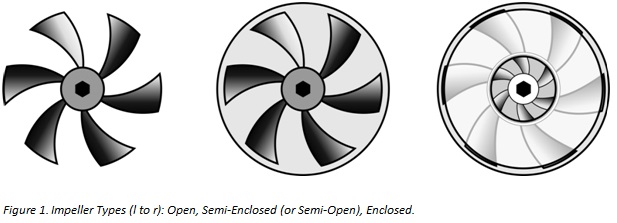

The impeller is the key component of a centrifugal pump. It consists of a series of curved vanes. These are normally sandwiched between two discs (an enclosed impeller). For fluids with entrained solids, an open or semi-open impeller (backed by a single disc) is preferred (Figure 1).

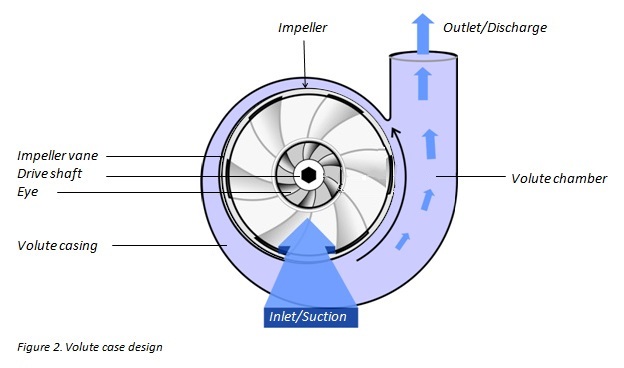

Fluid enters the impeller at its axis (the ‘eye’) and exits along the circumference between the vanes. The impeller, on the opposite side to the eye, is connected through a drive shaft to a motor and rotated at high speed (typically 500-5000rpm). The rotational motion of the impeller accelerates the fluid out through the impeller vanes into the pump casing.

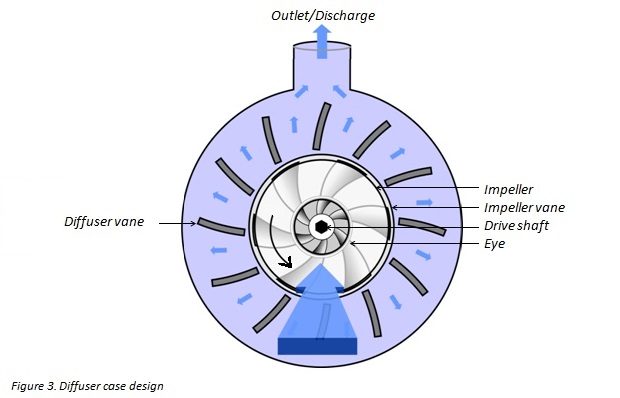

There are two basic designs of pump casing: volute and diffuser. The purpose in both designs is to translate the fluid flow into a controlled discharge at pressure.

In a volute casing, the impeller is offset, effectively creating a curved funnel with an increasing cross-sectional area towards the pump outlet. This design causes the fluid pressure to increase towards the outlet (Figure 2).

The same basic principle applies to diffuser designs. In this case, the fluid pressure increases as fluid is expelled between a set of stationary vanes surrounding the impeller (Figure 3). Diffuser designs can be tailored for specific applications and can therefore be more efficient. Volute cases are better suited to applications involving entrained solids or high viscosity fluids when it is advantageous to avoid the added constrictions of diffuser vanes. The asymmetry of the volute design can result in greater wear on the impeller and drive shaft.

What are the main features of a centrifugal pump?

There are two main families of pumps: centrifugal and positive displacement pumps. In comparison to the latter, centrifugal pumps are usually specified for higher flows and for pumping lower viscosity liquids, down to 0.1 cp. In some chemical plants, 90% of the pumps in use will be centrifugal pumps. However, there are a number of applications for which positive displacement pumps are preferred.

Technical Details

- Monobloc with extended motor shaft.

- Operate horizontally or vertically.

- Highly resistant construction.

- Hydroforming process Ebara patent.

- Enclosed Impellor.

Pump Technical Data

- Maximum working pressure: 10 Bar

- Maximum temperature of the liquid: -10°c - +90°c

Applications

• Water supply to civil, agricultural and industrial plants

• Pressure boosting

• Fire-fighting, heating systems and air-conditioning

• Moving industrial liquids

• Irrigation

• Refrigeration towers

• Swimming pools

• Emptying

• Washing plants

Pump has had very little use in an aqueous pre treatment plant and we are selling them in full working order, i.e. mechanically and electrically sound.

![]() Print / Download Ebara 3M/I 32-160/1.5 Centrifugal Electric Pump in Stainless Steel Datasheet

Print / Download Ebara 3M/I 32-160/1.5 Centrifugal Electric Pump in Stainless Steel Datasheet

Additional files

Ebara 3M/I 32-160/1.5 Centrifugal Pump Performance Curve

Photographs taken prior refurbishment. Our refurbishment service is not available on all machines.

Machines & equipment for sale

- Surface Treatment

- Cleaning & Degreasing

- Polishing & Belt Linishing

- Mass Finishing

- Ovens & Furnaces

- Process Cooling

- Shot Blasting

- Dust & Fume Extraction

- Air Compressors

- Rectifiers & Transformers

- Miscellaneous

- Latest Stock

- Special Offers

- Direct From Site Clearances

- Auctions

- Brand New Machines

- Available Immediately

- Sell Your Machine

Machine Alert

Get the latest machines emailed directly to you as they become available to buy online. Sign Up Now