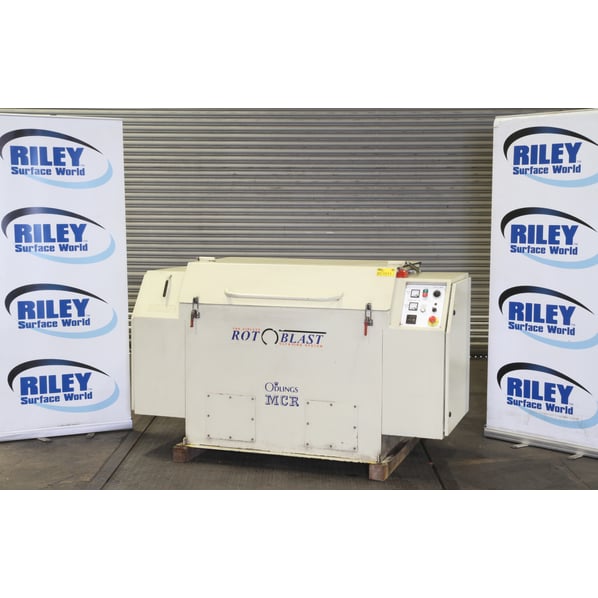

Odlings MCR R100 Rotoblast, Barrel Blast Machine

- Stock No

- SC1011

- Manufacturer

- Odlings MCR

- Model

- Rotoblast 100

- Year of Manufacture

- 2012

- Serial

- 00231R12

- Condition

- From a working environment, Excellent Condition

- Work Envelope (WxDxH mm) [?]

- Ø570mm x 1100mm long

- Work Handling Method

- Manual Load Auto Barrel Rotation Blast

- Other Info

- Twin Blast Motors & Drum Rotation

- Location

- Our Central Warehouse, Aldridge, UK

- Weight (kgs)

- 558

- External Dimensions (WxDxH mm) [?]

- 1860 x 825 x 1105

- Delivery Your delivery options

Description

Odlings MCR's Rotoblasts cabinets are ideal for automatically blast cleaning metal parts using steel shot delivered by twin turbines. i.e. airless operation.

The Rotoblast shot blasting cabinets have been used in various industries for blast cleaning parts like turbos, transmission cases, scaffolding clips, callipers and brake shoes in the re-manufacturing industries.

The automatic shot blasting cabinet is well built and reliable, making them the ideal workhorse of many re-manufacturing workshops.

Cleaning cycles typically take between 10 - 30 minutes, once finished the components are left rust free and ready to be repaired or repainted.

Automatic shot blasting cabinets use steel shot from grades S110 up to S550. The components which need blast cleaning are loaded into the steel carry cage which then rotates slowly whilst the base mounted turbine impinges the shot on the work inside. The Rotoblast turbine is constructed from toughened manganese paddles which rotate at 2500 RPM.

When the steel shot hits the components inside the automatic shot blaster, it removes rust or paint. Over the course of a shot blasting cycle, this process is repeated thousands of times.

The Rotoblast cabinet is filtered by a 180CFM extractor mounted in the side wall, removing any dust within the blast chamber.

The end result of the shot blasting cycle is clean components which are ready to be re-painted, repaired or re-manufactured.

Mesh hole dimensions - 17 mm x 17 mm sq.

Key Features:

- CE Certificated - Meets all current safety guidelines, several safety features are fitted.

- Rubber lined interior - Reduces noise and damage to the unit and blasting media.

- Tough Manganese shielded blast wheel.

- Integrated extractor - Keeps the working environment and components dust free.

- Easy to use - Simple operation that requires no supervision whilst processing.

- Safety - interlocked Lid and thermal overloads for added protection.

- Single Phase or 3 Phase.

- 3kW.

![]() Print / Download Odlings MCR R100 Rotoblast, Barrel Blast Machine Datasheet

Print / Download Odlings MCR R100 Rotoblast, Barrel Blast Machine Datasheet

Photographs taken prior refurbishment. Our refurbishment service is not available on all machines.

Machines & equipment for sale

- Surface Treatment

- Cleaning & Degreasing

- Polishing & Belt Linishing

- Mass Finishing

- Ovens & Furnaces

- Process Cooling

- Shot Blasting

- Dust & Fume Extraction

- Air Compressors

- Rectifiers & Transformers

- Miscellaneous

- Latest Stock

- Special Offers

- Direct From Site Clearances

- Auctions

- Brand New Machines

- Available Immediately

- Sell Your Machine

Machine Alert

Get the latest machines emailed directly to you as they become available to buy online. Sign Up Now