What is the Barrel Tumbling Process?

The tumbling process is used on an industrial scale for the removal of surface flaws caused by previous processes and for polishing the surface of components. Tumbling processes are used for the polishing of plastic, metal alloys, precious metals and natural metals. A tumble or barrel finishing process provides an action similar to rocks tumbling down a steep hill; the parts are placed in a barrel along with abrasive media, water, and agents. The rotation of the barrel causes the media mass and parts to tumble causing friction and grinding the parts in a mass. This movement produces a cutting action that results in an efficient way to deburr part´s surfaces.

What are the options for a great finish?

As with all finishing methods, the variables can vary the result greatly. Raw quarried stone tumbled in a wet slurry will produce very different results to delicate cutlery tumbled with walnut shell chips.

Below are some of the options that make a difference to the machinery and finish you need.

What Media is Right for You?

Media is the extra hard ingredient added into the tumbler to prevent parts from just banging together. Different media has different properties.

- Steel Media: heavy deburring, shining, polishing, and burnishing metal, plastic, or ceramic parts.

- Plastic Media: great at finishing delicate parts in a process that does not involve the excess wearing of work parts. Used for general metal deburring, precision deburring, polishing and burnishing. This type of media is used on softer metals such as aluminium or brass and on threaded parts.

- Ceramic Media: used for heavy, light and when fast deburring is needed. This type of media is good for heavy, and hard metals such as steel, and to remove rust on parts. Also used for general purpose polishing. Plastic, steel, stainless steel and aluminium parts are often polished using ceramic media.

- Organic Media: walnut shells can be used for medium to light deburring and for light finishing and polishing. Corn cob is used when finishing some metal parts because of its ability to absorb surface oils on the parts. Organic media is the natural, and safer way for the environment as they are biodegradable, durable and reusable.

Wet Tumbling Compounds

Wet tumbling compounds are used by mixing with solid media to deburr, finish and polish parts. If the media is treated with a cutting compound, there will be a grinding action and with a polishing cream, a smooth lustre will appear.

Speed of Barrel

The speed of the barrel is highly important; if it is too slow there will not be enough friction between the parts. The best results of the process depend on the work to be done and the size of the

barrel. Greater speeds will have a faster action but poorer finish, and slower speeds will take longer but will be safer for large or delicate parts.

Wet Barrel Tumbling: Involves the use of water as a lubricant

- Water level in the barrel depends on the desired finishing output: as water increases, you get a more refined finish and slower cutting rate.

- Water washes out the cutting residue to improve efficiency

- Barrels are lined with wood, rubber, neoprene, urethane, PVC or vinyl for better cushioning.

Dry Barrel Tumbling: Dry material is used as a lubricating agent or cleaning compound instead of water.

- Sand, ceramic parts, wood pegs, or corn cob can be used as dry materials.

Benefits of Barrel Tumbling

- Delivers consistent results than polishing by hand.

- Fast speed

- Equipment is versatile

- Mass finishing: machines can be designed to process a massive volume of parts as efficiently as possible. The barrel tumbling technique allows for processing many orders at once with little handling required.

- Tough technique: ideal for small and harder metal pieces that need a lot of work.

At Riley Surface World, we have barrelling and rumbling machinery to suit your needs. These machines can be used for wet and dry processes, and a variety of components can be cleaned and deburred.

S.M. Systems High Energy Horizontal Barrel Tumbling Machine

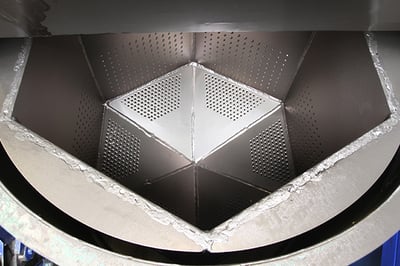

Super Fin centrifugal finishing is a unique high energy mass finishing process. In this machine, four barrels are mounted on the periphery of the rotating turret. The turret rotates in one direction and the four barrels in the opposite thus creating a high energy polishing/barrelling action.

- Stock No

- VC2223

- Category

- Barreling & Rumbling Machinery

- Model

- S.M. Systems Super fin SF 30

- Capacity

- 4 x 7.5 Litre Barrel - 135 dia x 490 mm

- Type

- Centrifugal Finishing Machine

- Other Info

- Infinitely Controllable Variable Speed

- Condition

- From a working environment, Excellent Condition, Current Model, Seen powered at RSW

- Refurbished Price [?]

- £ Login or Register for price.

- Sold As Seen Price [?]

- £ Login or Register for price.

Acton Vibrota type RB75 Parts Rumbler

A small single barrel rumbling machine for high quality, small component surface finishing. This small-scale, industrial barrel is designed to support media such as steel balls when surface finishing small components.

- Stock No

- VD349

- Category

- Barreling & Rumbling Machinery

- Model

- Acton Vibrota RB75

- Year of Manufacture

- Unknown

- Capacity

- 10 Litres

- Type

- Drum Tumbler

- Other Info

- 240 Volt

- Sold As Seen Price [?]

- £ Login or Register for price.

W Canning Centrifugal Spin Dryer - 45kg Capacity

Canning 45kg capacity, heavy duty centrifugal spin dryer with braked motor, sold as spares or for repair as the equipment does not meet the current health & safety at work regulations due to its age.

- Stock No

- VE2231

- Category

- Barreling & Rumbling Machinery

- Model

- W Canning 3 Gallon / 45kg

- Capacity

- Ø450 x 280mm

- Type

- Manual Operation

- Other Info

- Centrifuge spin off suds, oil, Heat Dry

Machines & equipment for sale

- Surface Treatment

- Cleaning & Degreasing

- Polishing & Belt Linishing

- Mass Finishing

- Ovens & Furnaces

- Process Cooling

- Shot Blasting

- Dust & Fume Extraction

- Air Compressors

- Rectifiers & Transformers

- Miscellaneous

- Latest Stock

- Special Offers

- Direct From Site Clearances

- Auctions

- Brand New Machines

- Available Immediately

- Sell Your Machine

Machine Alert

Get the latest machines emailed directly to you as they become available to buy online. Sign Up Now