Riley Heavy Duty 1200 Stainless Steel Wet Blast

New

- Price [?]

- Please call on +44 (0) 1922 45 8000

- Guarantee

- 1 year manufacturer guarantee

- Availability:

- Available subject to build time

- Condition

- Brand New, Current Model

- Stock No

- NEW140

- Manufacturer

- Riley

- Model

- Wet Blast 1200

- Condition

- Brand New, Current Model

- Work Envelope (WxDxH mm) [?]

- 1200 x 1000 x 1200

- Other Info

- 5 Year Cabinet Warranty

- External Dimensions (WxDxH mm) [?]

- 1600 x 1200 x 2000

- Delivery Your delivery options

Description

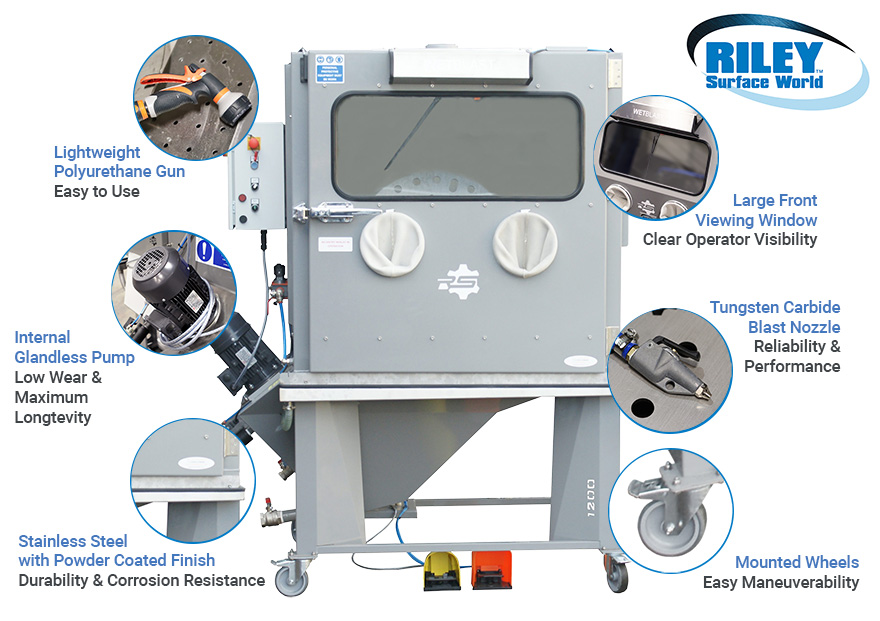

Riley "Wet Blast" Wet Blasting Cabinet

Our range of wet blasting machines is designed to simultaneously degrease and blast multiple components.

The process cleans by flow, and not impact, producing a 'soft' finish. The water acts as a lubricant, avoiding media impregnation and also extending the life of the blast media.

These are all 304 stainless steel constructed blast cabinets with an internally submersed glandless polyurethane pump and tungsten carbide tipped blast nozzle. These features provide extra reliability, life and lower servicing costs.

The pump bodies have been specially designed for minimal wear and longevity, due to the a combination of superior design and materials. They reflect the abrasive away from the surface of the pump thus drastically lengthening the life of the pump body.

In the unlikely event that the pump requires replacement, its price is a fraction of a standard pump.

Typical process is as follows:

- The water/media slurry is contained within the wet blasting cabinet sump.

- Delivery of the slurry to the manual blast nozzle is via a glandless polyurethane pump and associated hose located inside the wet blasting machine.

- Compressed air is added at the blast nozzle to accelerate the slurry and create the cleaning effect.

- After contact with the component, the slurry then drains back into the sump creating a re-circulating system.

Unbeatable Warranty

These blast cabinets include a massive 5 Year warranty on the stainless steel construction.

Electrical, pneumatic and general parts include a 2 year warranty and a 1 year warranty on submersible pump parts.

Features & Benefits

Please note - Video shows previous design before several improvements were made to improve easy of use.

Riley Wet Blast Machines come with an array of standard features

- Constructed from high quality 2mm 304 stainless steel for a longer service life.

- Fully powder coated in grey or white for easier cleaning and maintenance and corrosion resistance.

- Large front viewing window for excellent operator visibility, 6mm toughened glass.

- Automatic windscreen wiper and rinse which is activated with the foot pedal.

- Four anti-shadow LED lights for operator visibility.

- Right hand side door with double media catch trays.

- Media recirculating pinch valve to restrict reusable media going to waste.

- Door open safety switch for operator safety.

- Light weight nylon gun. All nozzles are silicone carbide inserts with an aluminium casing.

- Component wash off gun for a quick and easy rinse.

- Air blow off gun to dry off components.

- Lined, heavy duty, rubber gauntlets for operator comfort and safety (Size 10, 66cm, Level 4 abrasive resistance).

- Antistatic high tensile shot blast hose 12 bar 120psi max, 19mm inner diameter.

- Pressure regulator with gauge for fine adjustment to blasting pressure.

- Easy reach control panel with large emergency stop button.

- Side mounted pump to allow cabinet to placed back against the wall.

- Valve regulator mounted outside the leg to make maintenance and diagnosis easier.

- Plastic sedimentation tank.

- 3Kw thermostatically controlled sump heater to aid de-greasing with ON/OFF switch.

- 2.2kW media blast pump mounted directly into the sump.

- Submersible high-grade polyurethane slurry pump system (pump body, impellor, stirring nozzle) for longer service life.

- Open loop system as standard, plumbed into your water supply.

Optional Features

Some of these options can be added to wet blast cabinets we have in stock. Others may require a special order, please contact us to discuss.

- Rubber lining for rear or sides & rear

- Convert to single phase 16 Amp

- Stainless Steel gun holder

- Stainless Steel rotating wheel stand

- Alloy Wheel lift system

- Stainless Steel 700mm removable turntable

- Closed loop pump system with stainless steel sedimentation tank and filter roll carrier (ideal if no water supply or if using chemical treatments)

Service requirements

- Electrical supply 415v 3 Phase + Neutral

- Air supply 12mm (1/2”) nozzle: 35-45 CFM @ 60psi (Standard)

- Air operating range 2-6 bar (30-80psi)

- Water Supply 1/2" BSP

- Drain Floor Level Approx 10 Litres/min

- Ventilation 4" / 110mm Duct to outside atmosphere

- Noise Level: Blasting at 60 psi 75 dBA. Blasting an object 80 dBA

![]() Print / Download Riley Heavy Duty 1200 Stainless Steel Wet Blast Datasheet

Print / Download Riley Heavy Duty 1200 Stainless Steel Wet Blast Datasheet

Photographs taken prior refurbishment. Our refurbishment service is not available on all machines.

Machines & equipment for sale

- Surface Treatment

- Cleaning & Degreasing

- Polishing & Belt Linishing

- Mass Finishing

- Ovens & Furnaces

- Process Cooling

- Shot Blasting

- Dust & Fume Extraction

- Air Compressors

- Rectifiers & Transformers

- Miscellaneous

- Latest Stock

- Special Offers

- Direct From Site Clearances

- Auctions

- Brand New Machines

- Available Immediately

- Sell Your Machine

Machine Alert

Get the latest machines emailed directly to you as they become available to buy online. Sign Up Now