Why You Should Choose High-Velocity Fuel Coating (HVOF)

High Velocity Oxygen Fuel coating is a thermal spray coating process that is used to improve or restore a component´s surface. This surface engineering technique better enables life extension of equipment by increasing erosion, wear resistance, and corrosion protection. This process was developed in the 1980s, and is a subset of thermal spraying.

Using HVOF coating technique allows the application of coating materials such as metals, alloys, and ceramics to produce a coating of exceptional hardness, outstanding adhesion to the substrate material and providing substantial wear resistance and corrosion protection.

Advantages of Using HVOF Coating

- Enhanced protection against wear, corrosion, fatigue, oxidation and high temperatures.

- Lower oxide content due to less in-flight exposure time.

- Retention of powder chemistry due to reduced time at temperature.

- Smoother as sprayed surface due to higher impact velocities and smaller powder sizes.

- Higher hardness due to less degradation of carbide phases.

- Thicker coating.

- Reduced costs.

- Improved performance and electrical properties.

- Enables components to operate in higher/lower temperatures and harsh chemical environments.

- Improved efficiency and improved life of mating components.

Application & Materials

Thermal spray coating is an attractive technique because it offers a wide choice of materials and processes that have a reduced impact on the environment when compared to conventional processes. HVOF coating materials that are available for thermal spray coating include metals, alloys, ceramics, plastics and composites.

- Valve gates & seats,

- Mandrels,

- Ball valves,

- Rock Drill Internals,

- Pump impellers and internals,

- Sub-sea infrastructure components,

- Landing gear,

- Gas Turbine Components.

Process Details

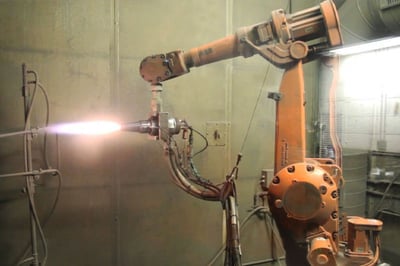

HVOF coating material is heated and accelerated by a gas stream to a component´s surface, to attain better properties. The gas stream is produced by mixing and igniting oxygen and fuel (gas or liquid) in a combustion chamber and allowing the high-pressure gas to accelerate through a nozzle. A powder is introduced into this stream where it is heated and accelerated towards a component´s surface. The resulting thermal spray coating consists of thin overlapping platelets.

If interested in machinery for high-velocity fuel coating, visit our Associated Process Plant & Equipment for our available stock or make an enquiry at +44(0)1922 45 8000

Machines & equipment for sale

- Surface Treatment

- Cleaning & Degreasing

- Polishing & Belt Linishing

- Mass Finishing

- Ovens & Furnaces

- Process Cooling

- Shot Blasting

- Dust & Fume Extraction

- Air Compressors

- Rectifiers & Transformers

- Miscellaneous

- Latest Stock

- Special Offers

- Direct From Site Clearances

- Auctions

- Brand New Machines

- Available Immediately

- Sell Your Machine

Machine Alert

Get the latest machines emailed directly to you as they become available to buy online. Sign Up Now