The Emergence of 3D Printing

What is 3D Printing?

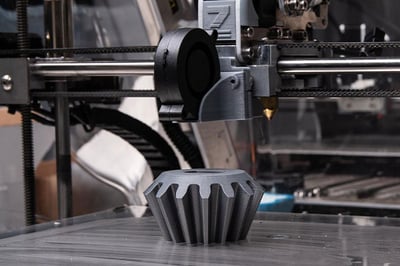

As the name suggests, 3D printing is a process making three dimensional solid objects from a digital file. The 3D printed object is achieved using an additive process, which is laying down layers of material until the object is created. 3D printers use a computer-aided design (CAD) to create 3D objects from a variety of materials, like molten plastics or powders.

3D printing, also known as “rapid prototyping” has enabled companies to develop prototypes quickly and more accurately; engineers, manufacturers, designers, educators, medics and hobbyists use 3D printing for a huge range of applications.

3D printers offer a variety of materials and techniques, they share the ability to turn digital files containing three-dimensional data into a physical object. In order to make a 3D print, a digital file is needed that tells the 3D printer where to print the material. The G-Code files are the most common file format for this- it contains “coordinates” to guide the printer´s movements, both horizontally and vertically (X,Y, and Z axes).

The most differentiating principle of 3D printing is that it is an additive manufacturing process that is based on advanced technology that builds up parts, additively, in layers. 3D Printers are very flexible, they can print rigid materials like sunglasses or flexible objects like phone cases. Some 3D printers can print with carbon fiber and metallic powders for strong, durable industrial products. This flexibility makes 3D printing a promising tool for the future of manufacturing.

Materials Used in 3D Printing

- Plastics: Nylon, or polyamide is commonly used in powder form- it is a flexible, durable, and strong plastic material that has come to be very reliable for 3D printing. ABS is another common plastic used for 3D printing- it is a strong plastic that comes in a wide range of colours. PLA is bio-degradable plastic material that has become more popular with time.

- Metals: Aluminium and cobalt derivatives are the most common metals and metal composites used for industrial 3D printing. Stainless steel in powder form is one of the strongest and most common metals used as well- it is naturally silver but can be plated with other materials to give it a bronze or gold effect.

- Ceramics: One thing to note is that when ceramic is used, it needs to undergo the same processes as any ceramic part made using traditional methods of production-namely firing and glazing.

Applications of 3D Printing

- Consumer Products (eyewear, footwear, design, furniture, jewellery)

- Industrial Products (manufacturing tools, prototypes, functional end-use parts)

- Car Manufacturing: spare parts, tools, jigs, fixtures and end-use parts

- Aviation: fuel nozzles

- Dental Products

- Architectural Scale Models and maquettes: 3D printed houses

- Reconstructing fossils

- Replicating ancient artefacts

- Reconstructing evidence in forensic pathology

Surface Finishing for 3D Printed Parts

Some pieces that are 3D printed are finished in order to enhance its appearance, improve its durability by increasing its resistance to wear, heat, corrosion or other elements, smooth out uneven surfaces, boost its electrical conductivity, or adjust its size and shape.

Many components are made of plastic, leaving them susceptible to damage from wear or impact, a metal coating can increase its strength to prevent this from happening. Other finishing options are sanding, bead blasting, shot peening, heat treatments, vibratory systems, tumbling, vapor smoothing, solvent dipping, epoxy coating, or painting.

Benefits of 3D Printing

- It has the ability to personalize products according to individual needs and requirements.

- It is a tool-less process that reduces prohibitive costs and lead times- components can be designed specifically to avoid assembly requirements with complex geometry and features created at no extra cost.

- It is emerging as an energy-efficient technology: creates less waste, reduces carbon footprint compared with traditionally manufactured products.

- Eliminates huge inventories and complicated logistics for shipping high volume of products around the world

- 3D printers can now be bought at an affordable price, opening the technology to a much wider audience

- It has the potential to bring production closer to the end user or the consumer, therefore reducing the current supply chain restrictions.

To read our full series of articles about 3D printing & additive manufacturing, check out the links below.

Machines & equipment for sale

- Surface Treatment

- Cleaning & Degreasing

- Polishing & Belt Linishing

- Mass Finishing

- Ovens & Furnaces

- Process Cooling

- Shot Blasting

- Dust & Fume Extraction

- Air Compressors

- Rectifiers & Transformers

- Miscellaneous

- Latest Stock

- Special Offers

- Direct From Site Clearances

- Auctions

- Brand New Machines

- Available Immediately

- Sell Your Machine

Machine Alert

Get the latest machines emailed directly to you as they become available to buy online. Sign Up Now