Romer Profispray Powder Coating Gun System

Finance available for variable duration and just the VAT value as a deposit.

Terms & Conditions Apply [?]

- Stock No

- GD868

- Manufacturer

- Romer

- Model

- ProfiSpray V

- Year of Manufacture

- 2024

- Serial

- A10S002.00442

- Condition

- Brand New, Unused, Current Model

- Work Envelope (WxDxH mm) [?]

- N/A

- Process Stages

- Single Stage

- Other Info

- Three Automatic Spray Programs

- Weight (kgs)

- 55

- External Dimensions (WxDxH mm) [?]

- 450 x 900 x 1050

- Delivery Your delivery options

Description

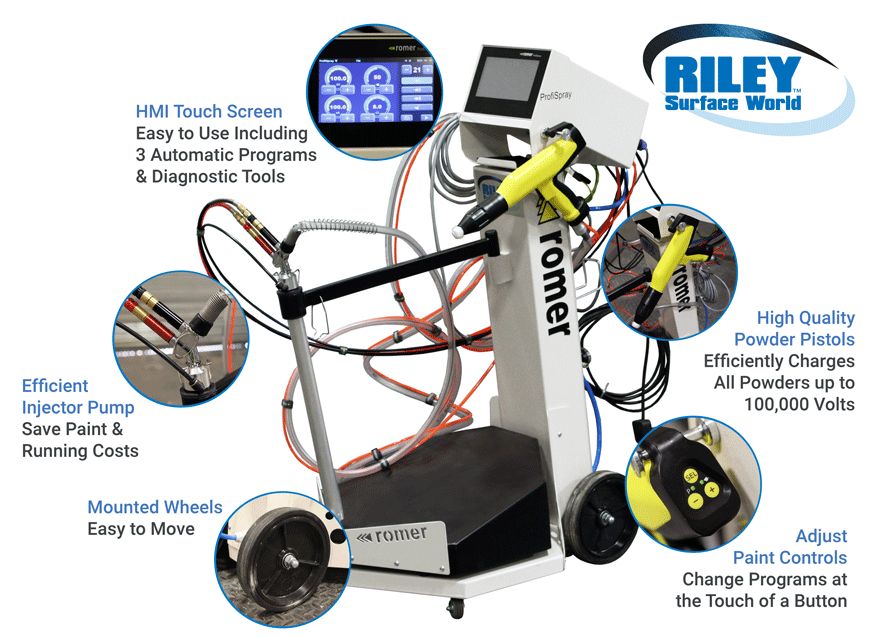

ProfiSpray V Powder Coating Gun & Station

The ProfiSpray V is built of the highest quality materials and incorporates the most advanced technological features of all the powder coating corona guns developed by Romer.

Romer Spray units are characterised by their ability to provide high productivity and efficiency rates in the application of sprayed powders. They offer a simple operation to deliver excellent coverage even in the most difficult to reach places with plastic or metallic powders.

Adjustment features of the powder gun allows for overlapping elements with a homogeneous powder stream, whilst also allowing you to control the thickness of the coating, giving optimum coverage.

Benefits

- High qualify finish achievable: built and tested by a company that powder coats components every day

- Efficient and highly productive: designed to operate in a high volume environment

- Easy to Adjust & Easy to Use

- Keep spraying part after part with auto diagnostics and cleaning

- 12 month manufacturer warranty included

ProfiSpray V Powder Coating Gun

A patented design in the US & EU the ProfiGun is a great option for heavy & light users.

- Electronic control improves penetration, reduces orange peel and back-ionization even with the most difficult of powders

- Accurate powder delivery with a digital valve control

- Up to 100kV powder charging capacity for better paint delivery onto components

- Light and easy for long term use with an ergonomic shape and balance

- One finger trigger operation

- Adjust paint flow and program from the gun

- Robust impact resistant materials

- Excellent operator grounding with the high-carbon conductive handle and powder hose

- Integrated air purge

- Easy to maintain and disassemble with replaceable powder path

- On-gun cleaning function selection

Powder coating injector

The Profijector powder pump is an efficient injector covered by European patents. It includes a the most efficient feed angle to save both paint and water giving lower running costs. Quick coupling makes maintenance easy.

Touch Panel and Control

- Easy to Use 7-inch touch panel

- Panel can be used with gloves

- Auto and manual spray settings

- Flexible and ad-hoc adjustment of voltage, current, powder and air

- 0.1kV and 0.1uA graduations in full adjustment range for great coverage of many paints and components

- 3 automatic programs (overcoating, hard-to-reach areas, flat surfaces)

- Name and store programs up to 20 programs

- Tailor fluidization, nozzle purge, current intensity curve in each program

- Sharp, standard and mild current intensity curves to suit paint and use case

- Advanced pneumatic valves to control the dose of air (patent pending)

- Real airflow measurement, responds to errors such as pressure drops or system blockages

- Quick Cleaning feature (approx 1 min run time)

- Advanced diagnostic tools with on screen troubleshooting

- Ability to control from external master controllers via ModBus protocol

- Maintenance help with service time counters (e.g. 200 hours for gun nozzle)

- Multiple languages supported

- Calibration, statistics and more advanced features.

Stand Features

Pulling together the great control features and gun is an easy to move stand. This robust maneuverable trolley with vibrating powder box platform includes handy features for storing the Profispray gun, hoses and cables. This includes an air preparation unit.

The inclined vibrating table allows all the powder to be used and the fluidised suction tube is optimized for constant powder delivery.

Nozzle & Spare Parts

For a complete application, the spray gun is adaptable with a variety of interchangeable spray nozzles capable of large surface areas to concave corners. The standard flat fan output spray is able to reach widths of 65° to 450mm away from the component for a solid paint application, along with the additional adjustable crevice nozzle attachment for precise & small areas.

Provided spare parts include: RI-1 Injector Kit, 4 Injector O-rings in two sizes (14 x 2.2 & 11 x 1.5), 2 Injector Filters, A Pump Nozzle Cartridge

Technical Specification

- Type: Electrostatic (Corona)

- Voltage input 220-240V

- Input pressure 5.5 bar

- Output pressure 0 - 6 bar

- Air quality/oil less than 0.1mg/nm3

- Hose length 5m

- Warranty period 12 months

Romer - Experienced Powder Coating Manufacturer

The outstanding feature of Romer ovens is the quality of manufacturing. Everyone who stands in front of a Romer, from buyers to calibration engineers, have commented how well constructed they are.

The outstanding feature of Romer ovens is the quality of manufacturing. Everyone who stands in front of a Romer, from buyers to calibration engineers, have commented how well constructed they are.

Romer have been manufacturing ovens and powder coating machines from their base in central Poland for over 25 years and export to 40 countries worldwide. Their 8,000m² facility employs over 150 staff and has passed Riley Surface World's inspection and auditing requirements.

Riley Surface World and Romer have secured a partnership to service the UK market with large (over 1m²) ovens up to 225°C and powder coating equipment.

![]() Print / Download Romer Profispray Powder Coating Gun System Datasheet

Print / Download Romer Profispray Powder Coating Gun System Datasheet

Photographs taken prior refurbishment. Our refurbishment service is not available on all machines.

Machines & equipment for sale

- Surface Treatment

- Cleaning & Degreasing

- Polishing & Belt Linishing

- Mass Finishing

- Ovens & Furnaces

- Process Cooling

- Shot Blasting

- Dust & Fume Extraction

- Air Compressors

- Rectifiers & Transformers

- Miscellaneous

- Latest Stock

- Special Offers

- Direct From Site Clearances

- Auctions

- Brand New Machines

- Available Immediately

- Sell Your Machine

Machine Alert

Get the latest machines emailed directly to you as they become available to buy online. Sign Up Now